Turnouts complete, trackwork not far behind!

It’s extremely gratifying to finally report a completion of a few things, since a lot of progress has taken place with the layout since I’ve written last:

Firstly, I’m done with turnout building and placement! This weekend I finished spiking down the switch just outside the Port Alberni enginehouse. This was the last turnout to be laid.

I still need to hook up a lot of servos, connect them to the Tam Valley Depot Octopus III controllers and figure out how they will be thrown. Dave Bedard favours toggle switches, I like momentary push buttons. It would be awesome if I could get Signalogic Systems SCP controls to work; I have them running the few tortoise-powered turnouts on the layout, and to have just one interface would be great. It’s bad enough to have bullfrog knobs and another means, to introduce a third might make things confusing for the operators.

On other “almost completed” items, I’m less than five pieces of track being spiked down from the milestone of being done laying all trackage. Two bits of track into the enginehouse (will it be a structure or just the foundation? I’m trying to determine -without a lot of success- whether the current enginehouse was built prior to 1988 or not. If you have any info on this, please drop me a line!), the Vancouver Island Gas spur needs its trestle constructed and then two lengths of flex track near the Port Alberni depot need to be spiked down.

Wiring has been done for the majority of the yard in Port; the southern quarter of the yard plus the remaining trackage towards the plywood division still needs feeder wires hooked up. Some bus wires will also need to be strung too.

Will have to update this post with pictures later, along with updates on a few other bits – the GP9 fleet, the freight car fleet and more. Stay tuned!

On complex track work

On April 27, 2014, I sent out the following notice to my operating crew:

Effective immediately, all Port Alberni freights are annulled, account lack of destination trackage.

I had pulled up the entire temporary staging yard in the space of a couple hours, salvaging the track and turnouts for later use, and that left any chance of a Port freight running to nil. In Hunt for Red October, Captain Ramius said that “on his arrival in the new world, Cortez burned his ships. Thus, his men were well motivated.” I had effectively done the same thing.

With the temporary yard gone, I could get to work on building the proper one, and after acquiring appropriate materials (ie: a full box of sheet cork and way too many strips), Cam and I got to work on laying that down and securing it with contact cement. (Seriously, anyone who uses white/yellow glue for cork needs to learn about Contact Cement.)

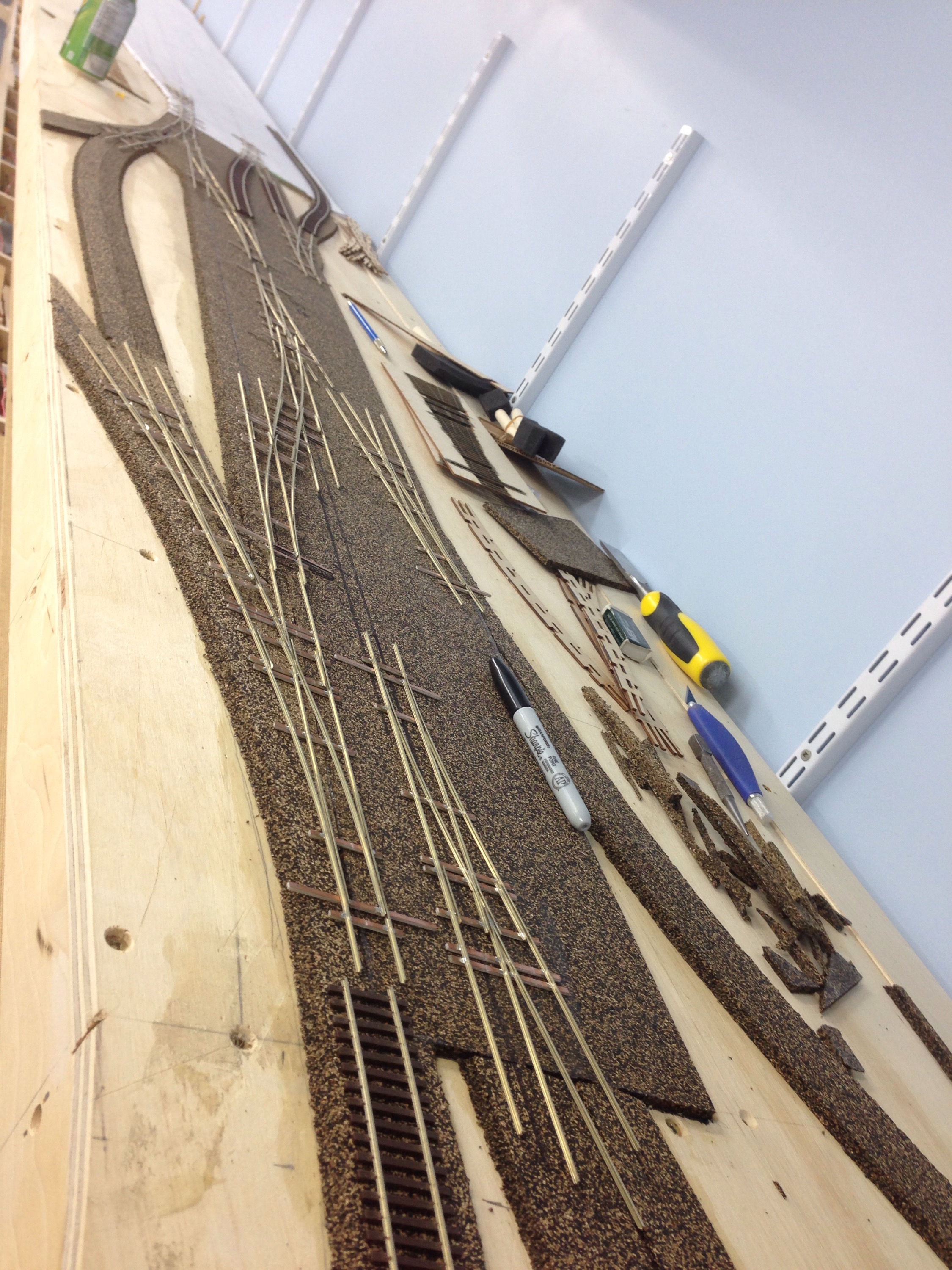

After that was all thoroughly sanded, tracklaying could begin. The first half of the Port trackage is rather complex. I spent on the order of several evenings fitting the skeletons of the turnouts together and discovered that I’ll have a route (not terribly likely to be used though) where you can travel about eight plus feet and not have the wheels touch any length of flex track – yes, all turnouts for 8 feet!

Fitting these turnouts together with a large amount of cutting, desoldering and resoldering bits to make crossovers, and butting points up close to the frog of the previous turnout all proved challenging but achievable. I would learn later that fitting the wooden quicksticks underneath would be just as much of a challenge.

The past couple weekends I’ve been getting the finished turnouts all spiked down and linked with bits of flex, along with trackage into the pulp mill.

I’ve got to spike this all down, but this represents the difficult stuff. The yard will be easy, but time consuming with all the drilling and spiking. The last spike is in sight, likely with completion of track work to be later this summer.

I’ve got to spike this all down, but this represents the difficult stuff. The yard will be easy, but time consuming with all the drilling and spiking. The last spike is in sight, likely with completion of track work to be later this summer.

Despite appearances, I have been working…

I will admit, having no updates since last October some six months ago is not doing many of you any favours. Allow me to bring you up to speed.

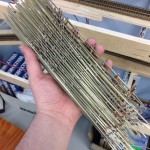

In my hand is the cumulation of some hundreds of hours worth of work. Many evenings and weekend mornings building these at my workbench, plus a few made elsewhere over these past six months and they are all done! Unless anything serious goes wrong, I won’t need to make another turnout for this layout.

Over two dozen functional turnout skeletons (as well as two more non-functional scenery turnouts, not shown) which need a wash and to be glued and spiked to the quicksticks, and then the Port Alberni yard can be laid in it’s intended trackplan. Speaking of which, the trackplan was finished up on the computer in a program called Empire Express some time ago and printed full size. Cam and I have been trying to figure out how to transfer it to the benchwork, and my ever-so-smart wife said I needed graphite paper. Sure enough, a couple art supply stores in Calgary stock large sheets of the stuff, at exceedingly reasonable prices: $1.80 for a 20×26″ sheet. Works much the same as the carbons of ye olde time. Place it between what you want to copy onto and your pattern, draw over the pattern and the paper leaves marks. Works for me. Except I have a temporary staging yard occupying the benchwork. Well, as of a few nights ago, make that ‘had’ a staging yard. Some judicious use of a soldering iron and a pair of nippers and the yard is gone. Track laying will commence rather soon…

Other updates:

I decided that the track plan for the plywood division wasn’t quite up to snuff and decided to extend the benchwork for it around the corner and into the stairwell. The trackage to the prototype was such that a train would continue out of the south/timetable west end of the yard past the depot, then into a short siding to allow the locos to run around the train, and push the cars into a facing point switch and the two tracks. Those two tracks are in the stairwell, with the runaround track where the staging was going to be. The engineering of the extension had to take the drawbridge into account which thankfully clears with about an inch of space.

Another update is for Courtenay. We weren’t happy with the number of moves needed for turning a Courtenay train and decided to do something. We’ve extended the siding track around the corner and it’s now long enough to account for a standard length train. Unfortunately the spur for the CP Express building at Courtenay is now single-ended as a result, but an acceptable compromise. The tail track is still long enough for a pair of locos, the water car and caboose.

GP9’s

Work continues on these. All shells have paint and most decals applied but still needing more, like frame dots, warning labels, etc. Work on the chassis still needs to happen in addition to decoder/lighting installs.

Pole loads

I’ve spent more than a few hours at Kevin Pyle’s drill press and have made quite a few poles. Sadly, only enough for about half a car’s worth!

And on a last note:

SUPERTRAIN, Canada’s largest model train show, is an event which I assist in organizing, happened a couple weekends ago. This year, the show was held only a few minutes walk away from my house and I took the opportunity to host an open house for a few friends visiting from out of town. Was surprised when they brought a few other friends. I’m rather proud that I had manufacturers (well, at least their reps) galore looking at my layout. Scott from Bowser, Matt from ESU, Jeff from Prairie Shadows, Dan from Rapido Trains, Grant from Southern Alberta Rail, and always, Michaelea from Sign Reflectionz. Cam, Mark Kaluza, Josh Anderchuk and Matt Soknacki were also there and fun was had by all. Next year guys, the trackage will be completed!

Fixing deficiencies

I suppose thanks are due here to a good friend of mine – Grant Eastman. Many times I’ve been to his very impressive N scale layout of the protolanced Southern Alberta Rail, and found substantial sections of benchwork and track completely replaced.

His motivation?

He simply didn’t like how it was previously done and decided to do something about it. For example, he didn’t like how one would have to leave the train and walk around the laundry facilities, furnace and hot water tank. So he relocated, not the track, but the latter three items to allow one to stay with the train. He rebuilt the staging loops and to provide a better track plan, rebuilt the stairway into the basement, changing it’s configuration in the process. He also changed all the code 80 track out with code 55, even in the fully scenicked areas for better appearance. I could go on but you get the idea. Enough about his layout and back to mine.

I wanted Vancouver Island Gas to be a signature scene on the layout, but disliked the fact the aisleway around the nose of the basement was tightened up substantially, and that the trestle was right up against said aisleway. Sure, I could protect the future structure and rolling stock with a sheet of lexan (high-grade plexiglas) but it did nothing to reduce the amount of dead space behind the track that would need scenicking.

So, after consultation with Cam and Dan, I decided to follow Grant’s lead and do something about it. Track was lifted, feeders cut, bus wiring separated, benchwork pried apart and then removed. Here’s a couple shots of the work in progress. The first shows Cam undoing screws to take off the benchwork and the next after everything save for the brackets have been removed.

Sadly, I neglected to take a ‘before’ picture as we jumped right into the work.

Some people showed considerable concern over the fact I was in demolition mode before the layout was even complete, but after reassuring them with why, they were supportive.

Several weekends later, the benchwork was reinstalled and track relaid and wired in. Thankfully, some pieces were reused, and only a few sections of track needed to be added in. Here’s a couple shots of what it looks like after everything was done:

The aisleway gained enough width (give or take another 7 inches), the space behind the track was substantially reduced and there’s space in front of the spur.

Sadly, one consequence of the work is the loss of the needed height to properly model the trestle. It’ll end up being compressed in both directions, but I couldn’t achieve that height without really impacting the space below. Oh well. I’m still happy I did this.

March 29 and 30, 2014

With my second ops session planned for just after SUPERTRAIN (good grief, what was I thinking?!?), I was thinking I should get something done for the layout. Not that Cam didn’t sort of prod me in that direction either, no…. (Insert shifty eyes here)

Anyway, we figured it’s be great to actually get a train all the way into Port Alberni, even if it ended up at a temporary staging yard of sorts, as I haven’t had time to focus on doing up a real, accurate track plan for P.A.

Side note here. Earlier, Cam and I were discussing the track plan and realized that the tight confines of the trackage near the wye in Port Alberni was a guide, but we needed to make sure what was planned was actually doable. As such, I’m going to draft up the plan in CadRail and then print it full size so we know exactly where things go. Needless to say, such a plan is going to take a while to fully draft.

For a very long time, we’ve had the sub benchwork down the hill started… But not quite complete. This past Saturday, Cam and I worked on fixing that, and getting that little bit of track board finished and secured. After a bit of a meal, we got the contact cement out and laid the cork from where we left off just prior to the MP25 trestle, all the way down the hill. As we weren’t going to put cork in P.A. until we had a plan, we used a long cedar shim to ramp the track from the cork to the plywood.

After dinner, track laying down the hill began in earnest, and that was complete that evening. Of note, we actually slightly superelevated the curves on the way down the hill, for some aesthetics, but more for keeping runaway rolling stock from wanting to jump the rails on the way down.

Sunday, Cam arrived and we got the temporary staging yard built. A three track, double-ended affair with commercial #6 turnouts, it’s not great looking, but will hold two full port freight trains… One to arrive and the power can switch the caboose off and put it on the other train and come back to Wellcox with a different train.

We cleaned up the layout after the trackage was complete, powered up the layout and ran a couple GP’s (3000 and 3004) up to Port to see how far we’d get.

Surprisingly enough, we got all the way to the yard, and into it!

July 27-28, 2013

“All that’s left to do is everything” -Jesse James

Probably the best quote I’ve got from The show ‘Monster Garage’ which aptly describes what we have done, and what’s still needing to be done after he cram sessions over the past couple weeks.

To summarize what has been completed:

Trackage in the staging yard is now complete, spiked down (required a trip to the hobby shop solely for track pins! And then another for more #71 drill bits, both account hard, and unforgiving, birch plywood) and (mostly) fed. I say mostly because there’s probably a dozen feeders still needing to be hooked up to the track bus and about as many needing to feed the microswitches powering the frogs in the staging yard. That aught to be fun…

We have servos installed and running on most turnouts, in fact, all the turnouts which must be electrically controlled, are, though I still have a ton of programming of the Quad-LN’s to do, routes to line, etc. I also changed out the accessory bus power supply with a 6A 12V power supply for the entire layout instead of having two running on the layout. I’ve also got a UP5 connected in the staging area too. To finish that bit off requires finding a spot for the Zephyr to live, wiring it in for the programming track at the end of the wye, and other linked tasks.

And then there’s the cleaning needed. This requires a massive amount of vaccuuming of everything, plenty of testing and generally making the basement hospitable. Did I mention that Jason arrives in a little over 36 hours?

July 13-14, 2013

A brief update…even though there was plenty of work done.

Over the course of the time spent downstairs on Saturday and Sunday, I got feeders dropped and secured to the rail for the entire ICG Nanaimo – Nanaimo depot sub-district. Not wired into the bus, but that will hopefully be completed this week. I also gapped the rails for that power district as well.

Cam was over for Saturday and some of Sunday and worked on getting track laid in the staging yard. Made really good progress too, having completed all but a few tail tracks on the southern end of the yard and half of the runaround track. Sunday saw the last bit of staging yard benchwork completed – that is, the reverse leg of the wye into the programming track, and a lot of that track is fitted, though still needs to be spiked down. We also found that cheap birch plywood has another nasty trait – loves bending the track pins! Coupled with the splintering capabilities, I can’t say I will recommend it for benchwork again.

I’ve also been working to get a servo programmed to become the block for errant rolling stock headed to the abyss. Mostly successful, but not entirely positive I can get the Singlet to function as I need it to – that is, having a microswitch operate as a toggle… More to come on that…

Cheers!

July 7, 2013

So it’s been a little while since my last post but I’m still working hard to get things ready for the end of the month.

Yesterday began with some cleaning of the basement – it’s a real disaster down there – and getting things lined up.

Since making the decision to go with servos instead of much larger and more expensive tortoises, I’ve acquired the Quad-LN’s from Tam Valley Depot, the servos, wiring and microswitches from eBay (servos for about $2.50 each, at my door, microswitches for 17 cents each, wires free due to a sharing deal with Dave Bedard) and after all is said and done, I have a DCC controlled turnout for less than the cost of a tortoise bought in a 12 pack… And that doesn’t include the other bits needed like a DS64 or the wiring involved.

Installation of these servos started yesterday and the Quad-LN’s were installed as well. Sadly, I neglected to order an aligner for the Quad-LN’s and the instructions indicate one is necessary to properly set them up. 🙁 I tried a few programming things but in the end, nothing did as it was supposed to, likely because the power supply I was using couldn’t pump enough juice. The Quad LN says it needs about 750 milliamps of power and the supply I used only provided about 300… So I’ve ordered an aligner and a 5amp power supply from Tam Valley. Hope to see them soon.

Meanwhile, Cam was busily getting turnouts laid in the staging yard. We’ve got a lot of track still to lay and I’ve got even more basement to clean up, track to wire and more to do…will get some more done tomorrow.

Cheers!

May 26, 2013

Simple update from yesterday’s small amount of work:

Installed six bullfrogs, and trimmed the throwbars to length. Also had to run to get #6 screws as that’s the only size which fits.

Tonight is running bus wire.

May 18, 19 & 21

This past long weekend was a very fruitful session of track building!

Following a lot of benchwork being completed over the previous weeks, we now have track laid pretty much all the way from just south of Bryn through to the Nanaimo depot. Yes, the saying, “we’ll cross that bridge when we get to it” applies here as last Tuesday, we now have track onto the drawbridge separating the staging trackage from the rest of the layout.

In addition to the great amount of trackwork done (which includes trackage into five industries), I’ve got bullfrogs built for all of the switches, though they still need to be installed.

And one last thing. Dan spent a bit of free time and punched a hole through the wall where the staging yard will come through the wall from the utility room.

No further track laying north!

The northern end of steel has been reached! Granted, wiring still needs to be installed in addition to some yard trackage in Courtenay, and some bullfrogs also need to be installed, but the mainline is in!

January 20, 2013

Wow, been a little while. Happy new year! I’ve been a little busy with getting things in place for SUPERTRAIN, and late this past week determined that I need to have the layout to a point where I can have a mini-ops session by the time mid-April comes around. I say mini because I’m wanting to show off the layout when a few friends arrive in town for the big shoe, but I know for a fact I’m not going to have Port Alberni in place in that sort of timeframe. Nanaimo, and staging, on the other hand, should be doable.

Spent an hour downstairs on Saturday and most of Sunday getting lots of little things done. Specifically, eight bullfrog switch machines and another turnout for Courtenay. Cam arrived in the early afternoon and set to work on the trackwork into Courtenay itself.

At the end of the afternoon, we’ve got track up to the south siding switch of Courtenay. So for the lower deck, needing to get everything around the walls wired, lay track in the Courtenay yard, lay track for the team track and ICG, and install the bullfrogs. Not much work really.

Which then leads to getting benchwork installed for the second deck, getting track installed and then comes the bigger question of exactly how I’m going to build/operate the connection across the aisleway to staging. We’ll (sunglasses) cross that bridge when we get to it.

December 29, 2013

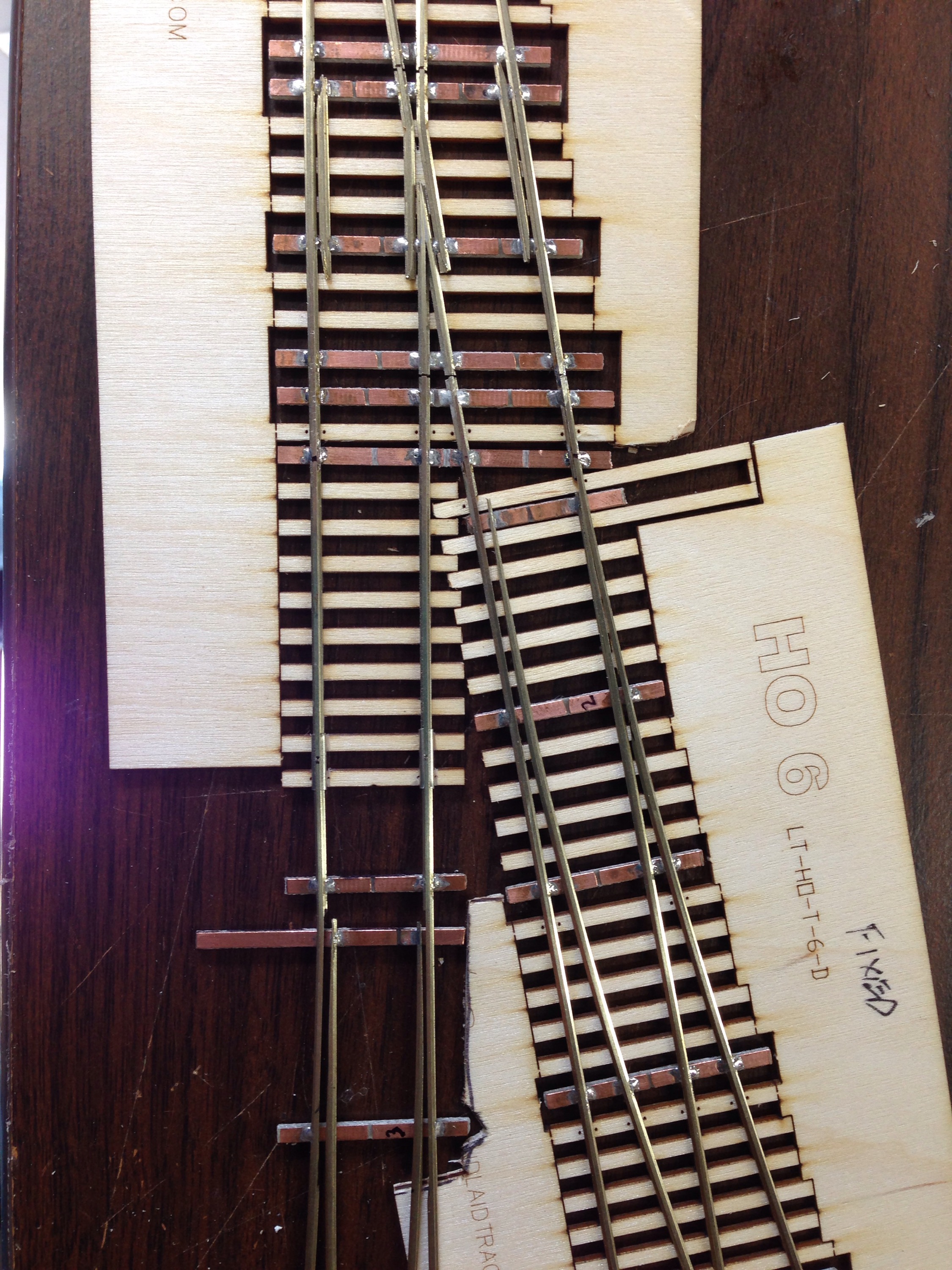

Spent this morning washing a bunch of turnouts and then assembling them with the quicksticks. Found one of the skeletons I thought was originally code 70 was actually a code 83 turnout which is for the staging yard. Oops.

Cam came over and we got to work on finishing the cork to Courtenay. After that was done, the track laying came. Cam got started with continuing the trackage north from Union Bay, and I started in on another turnout skeleton, occasionally providing my eyes to the progress and ensuring the track was kink free.

Dan arrived after he finished up work for the day around 6. He joined Cam with the track laying stuff, and I got to work on making the little clips to wire in the bus to the lower helix. Once there was a fair amount more track installed, I worked on hooking up feeder wires to the track. By the time 9:30pm rolled around, we were getting to the “done” point, and called it a day.

To sum up, we have cork down all the way to the northern end of track in Courtenay, only two turnouts need to be finished and track laid to just past BC Pole. A very good day of progress!

December (mumble), 2013

As much as I dislike Omnibus type things, I’m afraid I need to use it here…

I’ve been down to the basement quite a bit over the last few weeks and haven’t been doing any updates to the blog so my apologies to James and my other lurker readers for not doing these more frequently.

After getting the track boards cut, they spent a bit of time being left alone but they did get secured not long ago. Shortly afterwards, Cam and I cut a board and attached to the wall right at the bottom of the stairs. This will form the tail track and the northernmost trackage in Courtenay. This will come in handy for the crews working the Courtenay turn as they’ll likely need to do some shuffling of cars to switch on their way back to Nanaimo, as the vast majority of the turnouts are south facing.

I’ve also been busy building turnouts, mostly #6’s, but also a #8 curved turnout as well. Much as Cam would like Courtenay and the trackage into it to be arrow straight like it is in the prototype, my basement just won’t allow it, and I’d rather not give up a couple important industries (BC Pole and Dominion Tar) to accommodate that wish, so the turnout to the Courtenay team track will be situated on curved trackage. As far as we can tell, all industries in Courtenay in 1988 are present and able to be switched. I’m looking forward to operating it!

As we hosted a Christmas Brunch for a few important family members, I wanted to get the basement into some semblance of order and also do massive cleaning to make it presentable, I spent about three evenings getting a lot of cleaning/organizing/purging/etc. done. The results are fantastic. Family loved it, trains ran (though admittedly some dirty track in the helix caused some angst, more on that later) and all was good. I even spent the better part of a couple hours tonight doing the same to my workbench.

Couple days ago, spent a few hours in the morning to finish painting the stairs into the basement. Just plain white primer for now.

As I eluded to earlier, some dirty track has been bothering me. More due to all the dust in the basement, something rather unavoidable with all the construction happening, I decided to take advantage of the Boxing Day sale at PM Hobbycraft and looked at an Atlas track cleaning car. To the best of my knowledge, it’s the only vacuum equipped car, so picked it up and then proceeded to install a DCC decoder into it. I ended up removing all the wiring inside, hardwired the decoder in and after a bit of programming, am now able to control the speed of the fan. Ran it successfully through both helicies in front of a couple GP38’s. the results were promising. After a couple runs, the hopper was showing a few bits and the screen was covered in fine dust. The unit could definitely use a capacitor to assist the vacuum motor, and a couple other tweaks, but I’m satisfied with it. I’d post some pictures, but they’re too dirty. 🙂

Yesterday, spent a couple hours and laid some cork down through BC Pole and Dominion Tar as well as the mainline approaching both. Should have the rest of the cork laid tomorrow and probably some track soon as well.Had a real SOB of a time trying to get the lid unscrewed off the full 1.5L jar of contact cement though. I now own a couple strap wrenches…

Also received my order of track yesterday too. 10 bundles of code 70 flex, totaling 180′ of track, so should be good for a while. The three existing bundles weren’t going to make it to Courtenay. While we were out shopping, also picked up some 14ga stranded wire from MRO in red and black for bus wiring needs. My PSX-3’s finally arrived a week or two ago and I can get them installed.

Can’t think of anything else to mention. Thanks for reading this far!

December 2-5, 2012

So I’m finding the workflow with the registrar duties for SUPERTRAIN to be a little less hectic, and Cam found himself with a little extra time, so we got some additional work done downstairs. We’re now in the final stretches of getting all of the benchwork into Courtenay done. All the track boards, minus tail track well north of the Courtenay depot) are cut (including one spur I cut solo on Monday) and ready for installation!

We also checked the lengths and ensured we could fit at least a three-car pole set into both Dominion Tar and BC pole. And in fact, we could actually fit a five car set into the Dominion spur!

And over the past few evenings, I’ve been building turnouts again. I’m needing them and figured track installation is imminent… Two #6 turnouts are now built for the pole yards. Next up is the ICG spur in Courtenay, and then a curved 30/40 turnout for the Courtenay team track. Of course, the track into Courtenay is pretty much arrow straight, this making a curved turnout unwanted, but the layout dictated it to keep the number of separate curves down.

I’m also debating another open house this year after Christmas to show off the progress, but haven’t come to a decision as of yet. If you’re interested, drop me a line – either via email or a comment to the post.

July 2, 2012

Happy Canada Day!

A little belated to be sure, but I was offline (aka camping in an area without cell coverage) for the bulk of the weekend.

Came home last night festooned with mosquito bites and a few sunburnt areas and the cool basement was calling out to me. Naturally, I heeded the call, went downstairs and built a couple bullfrogs, spiked down about nine feet of track (the remainder of the main and siding at Arrowsmith) and put a few spikes into the turnout at the west end of the Arrowsmith siding. I also installed and tested the bullfrogs.

June 25, 2012

Cam called early this afternoon, said he had taken a couple days off work so he could not be at work on his birthday (the 26th, happy birthday!).

Asked what I was up to, I replied that I was making dinner and then headed downstairs to do some work on the layout and invited him over to take in the fun. So he did.

We pulled rolling stock out of Parksville and sanded the cork to the MP25 trestle location and then proceeded to fit track for the remainder of the Arrowsmith storage track and a few feet beyond. The other switch was also put into place.

We would’ve spiked it down and soldered various bits but it was getting late by then and I called it a night.

I’ll get the track spiked down sometime next week and wire up the track to a yet-to-be-installed bus but I’m definitely needing to find some dough to enable some more purchases… Specifically track, cork, benchwork material, and of course those shelf brackets!

At least in the meantime I can run a train to Arrowsmith…

June 20, 2012

Fitted and spiked down two 3′ long sticks of Flex last night… One for the siding and one for the main connected to the east siding switch at Arrowsmith.

Debated whether I sand the cork to enable more track to be laid and decided to do that another time.

June 18, 2012

I debated on whether I should even post a note about this, and ended up deciding to go ahead.

Last night, after considerable searching for rail joiners, spiked down the east siding switch for Arrowsmith. I also got a couple lengths of flex prepared for spiking down.

That is all.

February 19 & 20, 2012

I have an 8″ wide by 8′ sheet of 3/4″ plywood which unexpectedly got designated as a ‘holder of stuff’… Glue, contact cement, foam brushes, and various tools that never quite seem to make it back into the toolbox, but yet rarely used. It first started out on the benchwork that initially became Bryn, and when Bryn’s track was laid, we moved that sheet down. And then we moved it up when we laid track to Union Bay.

Well, this weekend we needed to move the shelf once again…This time to where we can keep it until scenery starts!

Cam came over on Saturday and Sunday and we finished off the trackwork out of the helix (yay! All helicies are done for trackwork!) and laid track to Arrowsmith siding. I hastily built a couple turnouts for the siding and then we got to benchwork. And did we ever go far!

Wrapped all the way around the end of the peninsula, and down the hill towards Port Alberni. Of particular interest is the fact it’s all supposed to be on a 1.7% grade from just past Arrowsmith all the way down to Port Alberni. I fully expect the port freight to really work but it’s going to be able to do the job without doubling the hill on account of the helix being a much heavier (and curvier) grade than the run up to the summit.

You’ll note I said “supposed to be”… Well, with what tools we possess, a digital angle indicator from Micromark, a really good vernier caliper and several levels and a pair of programs called “RiserCalc” and “GradeCalc”, we tried as best we can to make sure the risers are all at the correct height, cross-level and we still didn’t quite nail it. Some spots are a little steeper, and some less so. In the end, the digital level was discarded and the math made the grade. Looks pretty good.

When it came time to plan for how we’re going to incorporate Rogers Creek siding, we found a few things that didn’t quite work. Specifically, how to get a wider track spacing on the pieces of 4″ wide curved plywood… It would’ve required a sharper mainline radius, or purchasing another sheet of plywood and making poor use of it. In the end, we’re going to delete the siding from the plan on that plus the fact it would all be on a grade. Much as I’d like to have working handbrakes on my rolling stock, I just don’t see it in the cards, and I’m not one for sticking a pin up into the axles of cars to keep them on the grade in the siding.

At some point I’m going to need to get some dough and get going on the shelf standards and shelf brackets… I’m running out of benchwork I can build on!

Cheers!

February 12, 2012

A wonderful day!

Cam came over shortly after noon and we got started on working the track further up the helix. I had prepped the last few pieces of the benchwork earlier but Cam did the final adjustments before securing the track down.

After a bit of lunch, Dan joined us and we started working on the benchwork out of the helix towards Arrowsmith. After prepping a little more cork than necessary, we pressed on with the benchwork fully into Arrowsmith siding (admittedly, it was more of a storage track than an actual siding in 1988.) to be able to use up the cork.

I also cut off the top of a few ready rods close to where the track exits out of the helix.

A great day of progress!

January 28, 2012

And more helix! The port sub helix is now a couple turns taller after a good afternoon of Cam and I working away at the benchwork, track and wiring. One more full rotation for the track and we’ll be exiting the helix and towards the summit. And it all goes downhill from there!

January 21, 2012

In some respects, building a helix requires quite a few things to be done nearly all at the same time.

Such was the case when Cam came over to get some stuff done on the layout. Since we’ve pretty much done everything on the lower and middle decks, we started in on the upper helix to carry the track up towards the summit of the Port Alberni subdivision. We managed within the space of about two hours to wrap the benchwork around a revolution and a half, and a little over a half turn on the track.

And on a completely different topic…

I downloaded Google’s SketchUp, with the intent of learning how to model the stations along the line digitally in the effort of having the pieces laser cut, making the assembly effort to be better and hopefully produce a better finished piece.

We’ll see how things go…

January 2, 2012

Today saw the finishing of the turnout for Buckley Bay, the laying of track up to Union Bay, and the building and install of the bullfrog controlling the Buckley Bay turnout.

Of note with the track between Buckley Bay and union bay is the loose bit of track. No spikes, no soldering of the rail joiners. Possibly no feeders either.

It’s in preparation of the install of the bridge over Hindoo Creek, a short 15-tie long bridge, where we have some room to install bridges.

For the most part, the benchwork doesn’t allow for many bridges, owing to the lack of vertical clearance. Such was the fate for the Englishman River Bridge, but being on the lower deck, space below allows for these scenic features.

Also of some importance to the list of things done yesterday, and while we’re on the topic of bridges, is the install of the final bit of benchwork between the end of the peninsula and the straight stretch of grade into Port Alberni. Cam and I left this for a while trying to figure out how to handle the several inch drop from the benchwork around the top of the peninsula to the bit that was installed at the same height as Port Alberni itself. The benchwork was installed to be level with the port alberni height and one giant leap up to the next level. The extra clearance will allow for the install of the trestle around mile 25 of the Port sub. Here’s a picture of said benchwork. The high spot is on the right.

With the near completion of the trackage on the lower two levels of the peninsula, efforts will now start towards the completion of the main helix and trackage towards Port Alberni. About time we started paying attention to the Port Sub, beyond the little bit around the Parksville area…

Cheers!

Recent Comments