April 29, 2013

Finished up all the feeder wires and the bullfrogs in Courtenay this evening. Accordingly, I am now able to run freights all the way north… But until I get the layout vacuumed, nothing’s getting there!

Tricky benchwork

Spent a fair bit of time with Cam and Dan this past weekend. Saturday was primarily spent measuring, checking with levels, and a whole lot of cardboard being drawn on.

Now that the bridge is in, the work of getting to the staging yard is now underway. The big challenge is that there’s a wye into my future programming track and the main route to the staging yard itself happens to be in rather tight quarters. Specifically underneath the stairs to the basement and clearances in spots are tight as hell. Thus, the planning needs to be quite good because we don’t have ability to lay track on said benchwork after it’s installed. This also includes turnouts and their switch machines.

So the need to get it all bang on the first time is quite important.

Sunday had Dan and Cam over to start making lots of sawdust (and I just vacuumed it all!) in constructing the bits. Well, most of them. We’re still working on the one leg of the wye, but we ran out of time on that. More to come in weeks ahead.

Getting to old tasks

This past week has bee an interesting one. Of course SUPERTRAIN wrapped up last Sunday after a spectacular weekend and record attendance, and had a few people over to see the layout. Needless to say, Dan Garcia and Matt Soknacki of Rapido Trains were quite keen to see the layout as were a few others, including Steve Stark. Steve was introduced to me by Tim Horton (of BCR Dawson Creek fame, not the coffee shop) as a fellow E&N modeler. Steve is also an absolute fount of knowledge about the industries on Vancouver Island, and as a result of him, I’m needing to pull up a very short length of track at the end of the Superior Propane spur in Parksville and replace it with… Get this… Code 83 rail on Concrete Ties. Yup, there’s a 100′ long chunk of 132lb rail on concrete ties in the hydrogen peroxide facility. Yup, that spur was a dual-purpose bit of track according to Steve… Served as both hydrogen peroxide and propane!

In the past few evenings, I’ve also been taking care of a more necessary task, running bus wire and properly powering up the lower helix. After getting the bus soldered to the clips and then secured to the ready rod, gapped the rails at the lower end to ensure two boosters weren’t feeding a common set of rails, and made the connection of the bus to the appropriate PSX unit.

Fired up the system, did the quarter test and all good. And then I sent the Courtenay turn north from Parksville. Shortly after the train departed Parksville, I got sparks and beepage from the booster. Turns out that I have a DB150 which has the rail sync … Well, out of sync. A quick change of the output wires and problem solved.

Started the turn back down the hill and put the dayliner into service at Courtenay and had the two meet at Mud Bay. I suppose I should’ve taken a photo to commemorate the moment, but didn’t. Was having too much fun!

April 6, 2013 – The Bridge is in!

Really wanted to get some really meaningful progress done on the layout this weekend and made it happen. This past Wednesday, went down to Murray’s place and borrowed his router (and bits), and lined up assistance from Cam and Dan for Saturday.

We tore apart (again) the area around the Vancouver Island Gas spur, to allow for better scenery work, then built the trackboard down to the depot.

And then we built a bridge!

A fair bit of thought (and purchases) went into engineering and building this movable bit of benchwork, primarily because I vowed after hitting my head on a duckunder at CMT, that I would never have to bend over to get into the basement. Though there is a major crawl to get into the dispatcher’s desk, the rest of the operating session crew should never have to bend over to access any of the trackage. Anyhow, after much deliberation, we decided on a lift-up bridge rather than a swing bridge as originally intended for the access to points south of the Nanaimo depot. Lots of measuring, cutting, routing and then plenty of glue (of two types – the regular yellow carpenter’s glue and a polyurethane glue) were used to bond the wood and metal together. Here’s the bridge in the closed position:

And in the open position:

Yes, I know I need to install a doorstop or some such device to prevent the drywall from getting dinged too badly, but the hinges do assist in ensuring the bridge won’t fall down unattended, and provides some assistance in lifting it. It’s still very much a manual process to open or close, but it’s nowhere near as much work as it would be if there was no spring in the hinges.

I’m still needing something in the way of an alignment pin to keep a lateral alignment certainty but the brass latches on the underside make sure the vertical transition stays as it should.

We also need to get cork and track laid, but it’ll likely be after SUPERTRAIN before that happens owing to the time needed to build two curved #8 turnouts, two #7 straights and two #6’s for the trackage needed up to the bridge.

I should also really get the wiring finished for the lower helix and the rest of Courtenay yard too… Lots to do for sure before the next major bit of benchwork: the Staging Yard!

Cheers!

The past few weekends, and a Good (progress) Friday!

So I’ve been busy, and to be honest, not terribly inspired to write about the progress made on the layout.

But progress has definitely been made! A few weeks ago, I did a fair bit more wiring work to the Courtenay site, and we can (in theory) run trains all the way to the depot in Courtenay…. Which is good for the dayliner, but not for the Courtenay turn which needs access to all trackage in the town to do what it needs to do. That will come in time.

But more importantly…

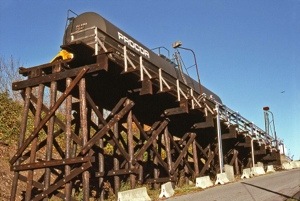

We have benchwork into Nanaimo! Cam, Dan and I worked over the past couple weekends to get benchwork built and this past (Good) Friday, Cam and I got track boards installed south to Vancouver Island Gas. This spur is rather interesting because of … Well, here’s a picture that explains it all:

Cam and I have also worked out a solution for the bridge across the aisle to the staging yard. Instead of being a lift-out or a swing bridge, we decided on something more resembling a bascule bridge. It’ll swing up to vertical over the fridge, and the best part, we’re using self-closing hinges. The weight of the bridge will keep the pressure light when the bridge is down, but assist in raising it and will also ensure it stays open when it’s up. Of course, given the fact we need to incorporate a grade along the line to the VI Gas spur means we’ll need to incorporate some mechanism to keep rolling stock from going to the great abyss if it’s not connected to a locomotive!

That we’ll figure out over the next while…

Till then,

Cheers!

Recent Comments